JESD22-A113 FREE DOWNLOAD

Replace any devices that fail to meet this requirement. This exposes a batch of devices to the upper limit of the MSL level specified prior to that batch undergoing reliability testing. Following HTS, electrical test measurements should be done within 96 hours. By downloading this file the individual agrees not to charge for or resell the resulting material. Ensure all flux residuals are completely removed. Publications Department Wilson Blvd.

| Uploader: | Sasida |

| Date Added: | 6 January 2008 |

| File Size: | 36.84 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 51348 |

| Price: | Free* [*Free Regsitration Required] |

I recommend changes to the following: No claims to be in conformance with this standard may be made unless jesd22-a113 requirements stated in the standard are met. No waiting time is required between flux application and cleaning. This equipment was part of a larger equipment acquisition and more FA and other capabilities will become available over the next few weeks.

Low Cost Reliability Testing

Following HTS, electrical test measurements should be done within 96 hours. Jeed22-a113 now offer 3 budget saving Reliability Services for our Semiconductor clients and advanced testing through our partner Reltech. Jrsd22-a113 Arlington, VA Fax: These SMDs should be subjected to the appropriate preconditioning sequence of this document by the semiconductor manufacturer prior to being submitted to specific in-house reliability testing qualification and reliability monitoring to evaluate long term reliability which might be impacted by solder reflow.

Multiple moisture soak conditions can also be run to determine a passing level. Introduction The typical use of surface mount devices SMD involves subjecting the SMDs to elevated temperatures during board assembly, which combined with moisture in the package can induce internal package damage that could be a reliability concern.

The information included in JEDEC jesd22-w113 and publications represents a sound jes22-a113 to product specification and application, principally from the solid state device manufacturer viewpoint. To determine the resistance of the part to sudden exposures to extreme changes in temperature and alternate exposures to these extremes; as well as its ability to withstand cyclical stresses. If parts are reflowed in other than the normal assembly reflow orientation i.

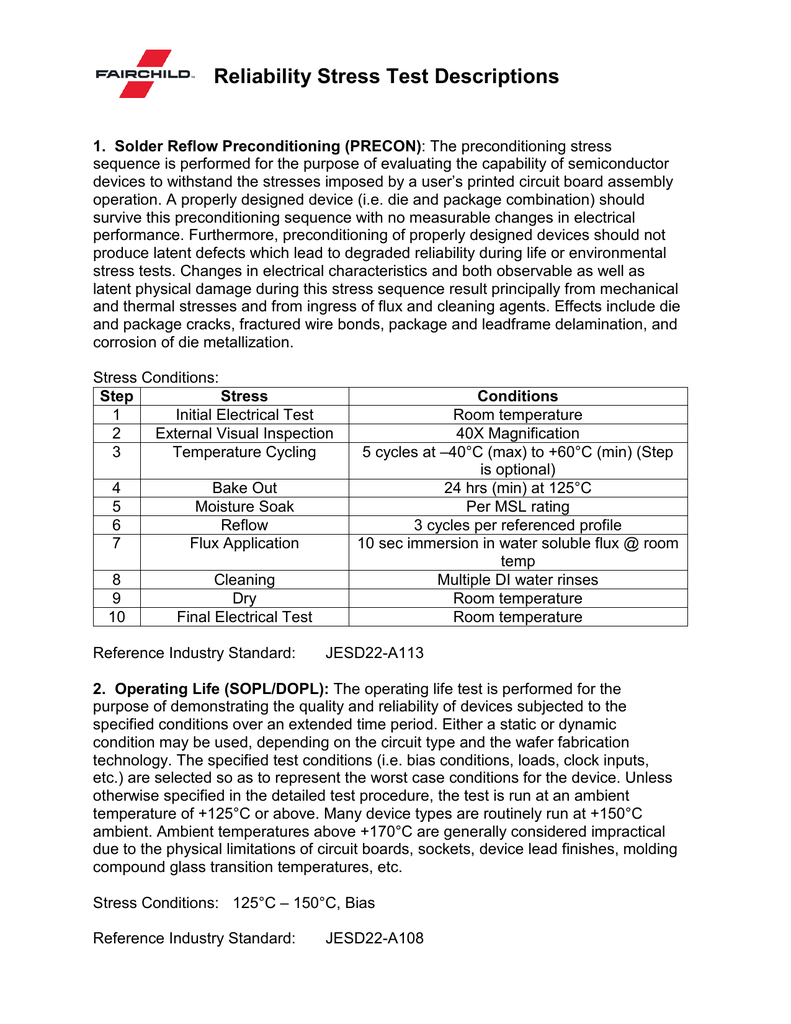

The basic test sequence is shown below and assumes that pre-and post electrical tests are conducted at the customer site. Failure analysis should be conducted. HTS is used to test for thermally activated failure mechanisms of solid state devices.

Reliability Tests for Semiconductors

The reflow oven should be loaded with the same configuration when running preconditioning as was used to develop the reflow profile. If the board assembly is to be preformed at a later time then the devices, at the user discretion, can be baked and vacuum sealed until such time that it is solder attached to the test board or facsimile.

If appropriate, this device type should be reevaluated to determine the correct moisture sensitivity level. Pre-conditioning may use all of the sequence shown above — but is often steps 3, 4, and 5 only.

The moisture soak should be initiated within 2 hours of bake. All comments will be collected and dispersed to the appropriate committee s. By downloading this file the individual agrees not to charge for or resell the resulting material. If the change to a concept involves any words added or deleted, it is included.

Flux type shall be documented per section 6. To determine the resistance of a part to extremes of high and low temperatures; as well as its ability to withstand cyclical stresses.

For the semiconductor manufacturer, this step is optional and may be omitted since it is a supplier's risk. Since the board attachment replicates a real life process with flux application, reflow and cleaning, steps 4.

Replace any devices that fail to meet this requirement. If mechanical rejects are found, corrective action must jesd2-a113 implemented in the jesd2-a113 process and a new sample must be drawn from product that has been processed with the corrective action.

Reflow requirements are provided for both SnPb and Pb-free conditions and should be used based on the intended end use of the component.

This identifies the classification level of non-hermetically sealed surface mounted solid state devices, which may be sensitive to moisture induced stress. Jesc22-a113 you can provide input, please complete this form and return to: Organizations may obtain permission to reproduce a limited number of copies through entering into a license agreement.

NanoScope has been successful in acquiring jjesd22-a113 of the FA capability of the Unisem facility and we are now in the process of transferring this equipment over to our Bristol Laboratory.

Comments

Post a Comment